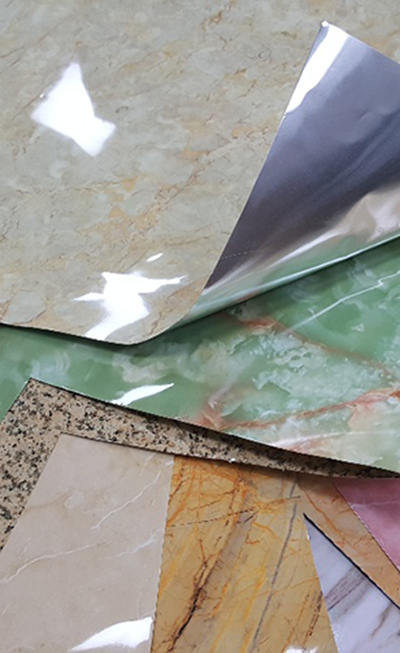

Do I need to know the process and application of baseboard transfer film? The baseboard transfer film is suitable for use in large-area or special-shaped substrates, and the effect will be better, but we can understand more effectively when using this type of baseboard transfer film , The following five-point steps can come together to understand!

Baseboard transfer film

1. Select the substrate that has been sprayed or electrophoresed

2. Wrap the transferred substrate with wood grain heat transfer paper, and fix the interface of the paper with high temperature resistant adhesive paper to prevent the wood grain heat transfer paper from loosening. (Note: The front of the wood grain thermal transfer paper should be attached to the face of the substrate to be transferred.)

3. Put a plastic plastic bag with high temperature resistance and good sealing on the substrate wrapped with wood grain thermal transfer paper, and then evacuate from both ends of the plastic bag until the plastic bag is sufficient. Effectively adhere to the substrate. The size of vacuum negative pressure should be adjusted appropriately according to the characteristics of the substrate to be transferred and the negative pressure that the plastic bag can withstand, usually between 0.3 and 0.8Mpa. (Note: The purpose of using plastic bags is to force the plastic plastic bags that have been close to the substrate to force the wood grain thermal transfer paper to fully and effectively adhere to the substrate through negative pressure.)

4. Send the wrapped substrate to the oven for baking. The level of baking temperature and the length of time should be appropriate according to the characteristics of the substrate to be transferred, the depth of the texture to be transferred, and the specific performance of the oven. Adjust, the transfer temperature is usually 160 ~ 180 ℃, the time is 5 ~ 8 minutes

5. Take out the transferred substrate from the oven, pull the plastic bag from the end of the transferred substrate (Note: This plastic bag can be used repeatedly for profit), tear off the thermal transfer paper and make the surface clean.