The main material for hot stamping is anodized aluminum, also called hot stamping foil. It is mainly composed of two thin layers, namely polyester film substrate and transfer layer. During hot stamping, the transfer layer is imprinted on all or part of the surface of the printed object by the effect of heat and pressure. When the hot stamping is completed, the polyester film edge is torn off together with the part that has not been transferred.

The hot stamping process is divided into four steps:

1. The hot stamping foil is in contact with the substrate;

2. With heat and pressure, the thermal transfer layer is fused and transferred to the surface of the substrate;

3. Remove the pressure and peel off the polyester film;

4. Feed the hot stamping foil and replace it with the substrate to be hot stamped.

The perfect hot stamping effect mainly depends on the level of coordination with temperature, pressure and hot stamping time. In addition, it is also necessary to consider whether the substrate, hot stamping machine, hot stamping machine fixtures and pads are suitable. Finally, let's study the environmental conditions, including indoor temperature, substrate temperature, indoor air cleanliness (dust content), temperature, etc. .

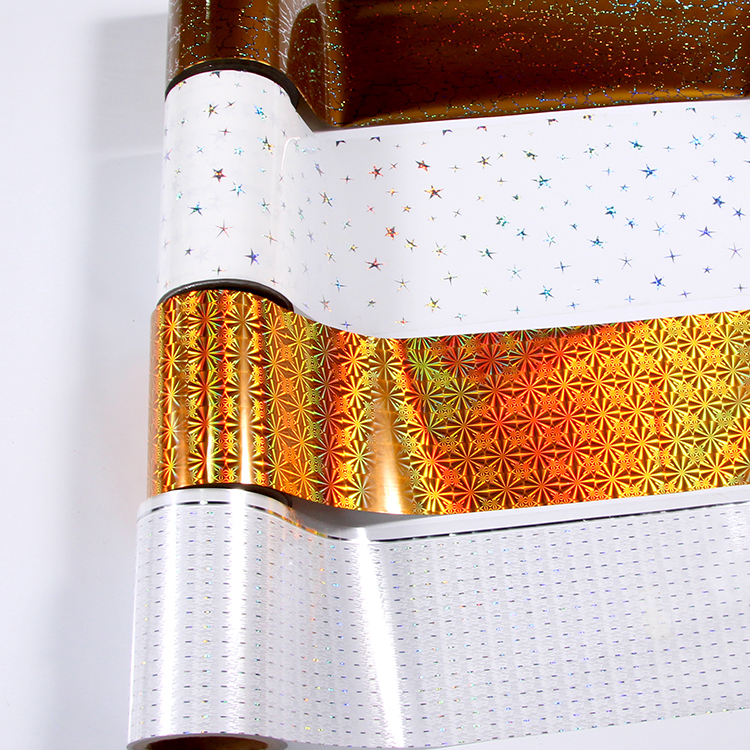

1. Hot stamping foil, there are two types of roll and single foil, the roll can be divided into different models according to the printing material. The influence of many factors such as the suitability, speed, temperature, pressure, quality of hot stamping plate and padding technology between the anodized aluminum and the iron bearing material, the tension adjustment of the anodized aluminum, and the condition of the hot stamping machine. The proper speed, temperature and pressure of hot stamping are the most important. Various models of anodized aluminum have different properties and different printing materials.

2. Hot stamping temperature. If the hot stamping temperature is too high, the hot stamping will lose its metallic luster and blisters. The edges will not be clear or even paste.

3. Hot stamping pressure. Excessive hot stamping pressure will cause paste or handwriting to become slurred. The hot stamping pressure is too small. The hot stamping foil and the substrate cannot be adhered, and the hot stamping part of the hot stamping foil cannot be cut. The installation of hot stamping foil should not be too tight or too loose. When it is too tight, the handwriting is missing from the pen, and when it is too loose, the handwriting is not clear.

4. Hot stamping speed, which actually reflects the contact time between the substrate and the hot stamping foil during hot stamping, which directly affects the fastness of hot stamping. If the hot stamping speed is too fast, it will cause hot stamping or imprinting. ; The stamping speed is too slow, which will affect both the stamping quality and production efficiency.

During the hot stamping process, speed, pressure and temperature are mutually restricted, and its process parameters are always determined in the order of hot stamping speed, pressure and temperature. First determine the hot stamping speed. Under normal circumstances, it is treated as a constant and not easily changed. Then find out the suitable stamping pressure and stamping temperature. This simplifies the operation procedure and also easily controls the quality of hot stamping.

5. Hot stamping machine, according to the hot stamping method, the hot stamping machine can be divided into flat pressing, round flattening, and round pressing round; according to the position method of the hot stamping plate, the hot stamping machine can be divided into vertical and horizontal .

6. Substrate, hot stamping is also called substrate. Substances for hot stamping of printed matter include offset paper, coated paper, white cardboard (cardboard) textured paper and varnished cloth, plastic products, etc.

In addition, resin plates can also be used for hot stamping instead of copper-zinc plates. As long as the temperature and pressure are well coordinated, good products can also be hot stamped. 1) The temperature control is very critical. It is directly related to the quality of hot stamping. If the temperature is too high, the resin plate will also be burnt. The hot stamping foil will also cause sticking due to the temperature. The temperature should be determined according to the quality of the tree version. 2) Due to the toughness of the resin plate, there is no need to use too much pressure, and the handwriting will be very clear. 3). Double-sided tape for fixing the resin plate, this tape will not affect the heat insulation, and it is easy to grasp the temperature.

The operator of the hot stamping machine must concentrate, work with hands and feet simultaneously, and keep a certain distance to the hot stamping version to avoid accidents. For machine adjustment, please read the random instruction manual carefully.